Around Beauty Meetup #7: A philosophy to create value for customers who share in developing tiles and cosmetics

2021.01.25The "Around Beauty Meetup" is a gathering of various innovators in and outside the company related to beauty.

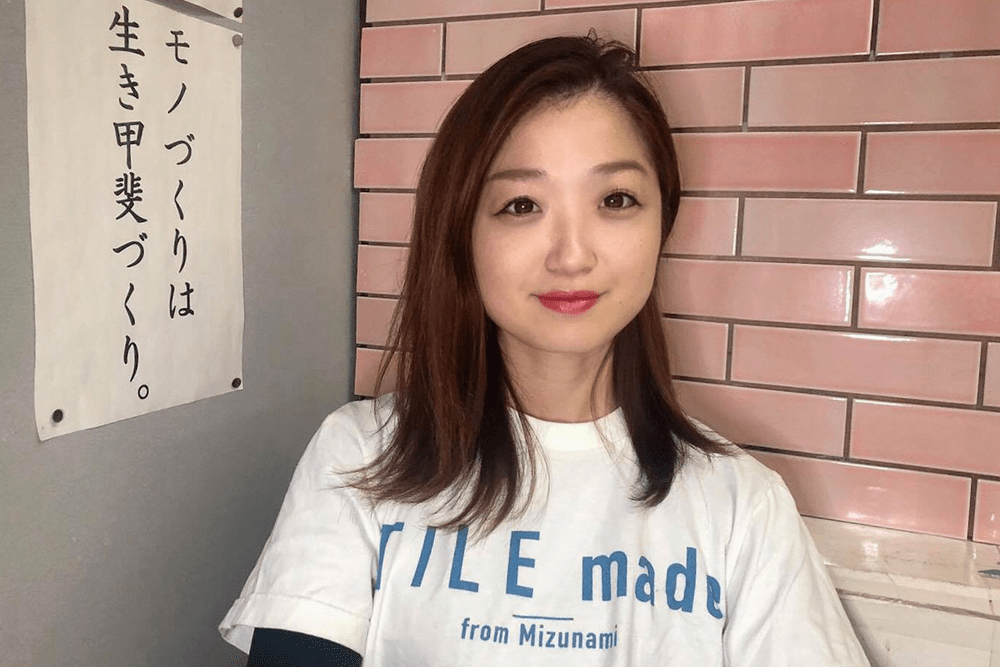

The 7th event was held under the theme of "customer-oriented manufacturing" through the creation of new styles of tile that utilize the glazing technology that has continued since the Nara period. Yukie Tamagawa, the representative of Protob LCC and TILE made, who launched TILE made, a tile brand that leverages glazing technology to convey the appeal of tiles made in the Tono region of Gifu Prefecture, famous for ceramic products, was invited as a guest speaker. She discussed the glazing technologies that seemingly differ from cosmetics, but have many common features, as well as their attitude toward manufacturing.

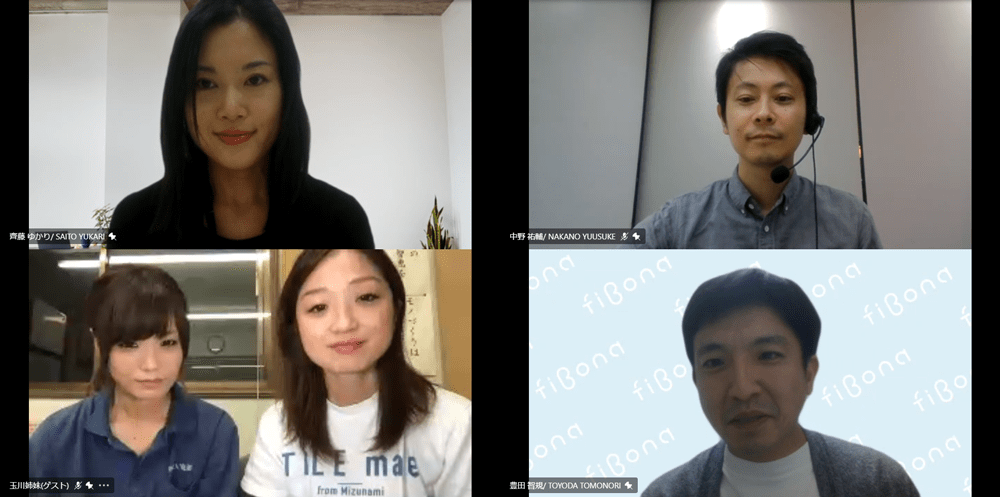

This Meetup was also held online. In addition to participants from the Shiseido Global Innovation Center, a variety of organizations and companies engaged in activities related to manufacturing participated.

At the beginning of the meeting, Tomonori Toyoda, a member of fibona who served as the host, said this about the theme, "Tamagawa-san's glaze uses a traditional glazing technology that gives color and gloss to things like kiln-fired items. I think there are many things in common with our cosmetics technology and how we are shifting these to the needs and values of our customers, so I would like to discover what we can learn through discussions and maybe learn something we can be a hint for the next action."

Challenge to create spaces in new genres that transcend the boundaries of tiles

In the ice breaker after the opening, self-introductions were carried out. Through everyone’s hard work and communication, the sense of distance between participants shrank despite being online, creating an inviting and engaging atmosphere.

After the ice breaker, Ms. Tamagawa's guest presentation began.

A glaze is a glassy film covering the surface of ceramics. Ms.Tamagawa launched her brand called TILE made which uses the glaze-based technology of the family business Tamagawa Glaze inc., and proposes, plans, develops, manufactures, and sells tiles with a particular focus on color gloss. TILE made is not merely a brand that offers tiles, but is trying to "create spaces for new genres that transcend the boundaries of tiles" through the brand.

At the beginning of the presentation, Ms.Tamagawa talked about the current feeling surrounding glazing.

"The glaze manufacturer is usually like a behind-the-scenes supporter. They are positioned like a subcontractor of a tile maker, and most customers think that the tile maker designs the colors and textures as well. In fact, the technology for this coloring and texture is supported by the technology of the glaze maker. I have watched the family business closely, and I have come to feel that it is a waste to remain a behind-the-scenes supporter while the technology is there."

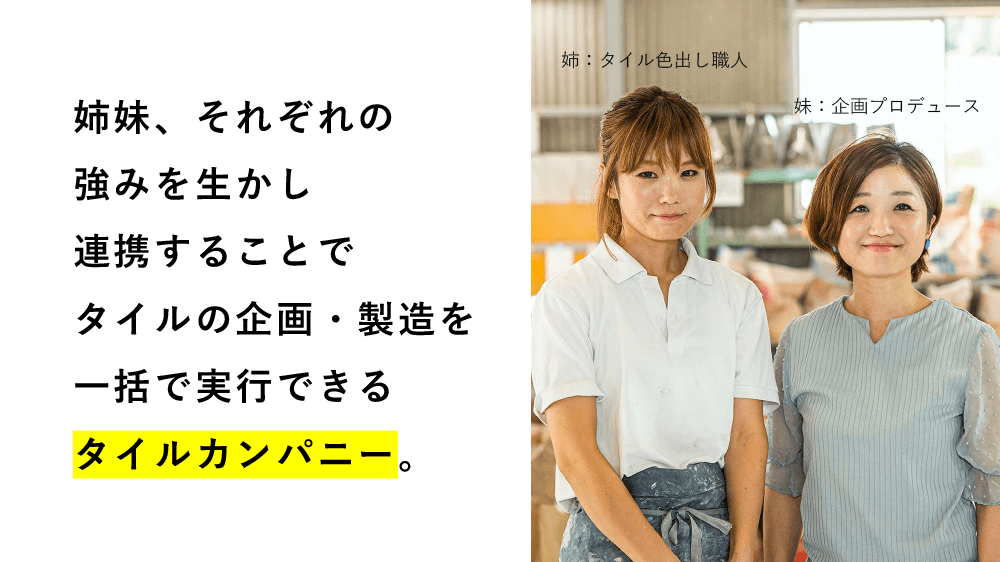

TILE made develops tiles for customers by reproducing the places based on photographs and images that bring to mind vibrant colors and travel destinations, and by reproducing old-fashioned tiles that are already used in interiors and other areas. Ms.Tamagawa planned and produced the tile, and Hiroko Ido, a glaze craftsman and Ms.Tamagawa's older sister, played a role in the color of the tile. They handle the business by utilizing each other's strengths.

The spirit of craftmanship engraved in DNA

Following this, Ms.Tamagawa, talked about the details of the launch of TILE made and her thoughts. She dropped out of university the moment she heard "Let's go into the family business," and worked with glaze at Tamagawa Glaze inc. for six years. Ms.Tamagawa said she went to Tokyo, gained experience in various companies, and started up a current Protob LLC.

Ms.Tamagawa decided to work in the family business and set up TILE made because of the presence of her father who was also a glaze craftsman. "My father is "The artisan" who doesn't talk about anything. He has been making glaze for more than half a century, but he is a cool father who says many things I don't know about yet. I think it's my starting point to look up to my father and make things. I started my business out of the desire to somehow liven up this world."

As she was involved in the family business, Ms. Tamagawa had noticed several things.

Tiles are usually mass produced by machinery. At the time, she noticed that the glaze manufacturers made a considerable number of sample tiles by hand in various forms to make colors, and also that they were able to manufacture goods with a high degree of freedom that led to value by producing colors by hand in addition to mass production by machines.

Aside from the planning and production that Ms. Tamagawa is in charge of, she also does things outside of the family business. She planned and promoted volunteer garbage pickup when she left her family business and went to Tokyo and abroad. I found that normal garbage pickup is a fun experience with one idea and one plan. The activity of picking up garbage is seen by many people, and we’ve continued doing it for over ten years. The activities were named “Green Bird” and it also led to the creation of 70 teams nationwide cleaning up towns with about 30,000 people each year. It is easy to see how much it has grown.

You can produce interesting things by focusing on your feelings and thinking in new ways. I use my experience in manufacturing, thinking that working in the family business, dealing with the community, and all things would work out.

After a lot of experiences and learning, Ms. Tamagawa, who launched TILE made in 2017, started hearing from a lot of people, including architects, about the current challenges of tile. "In the past, the oven was unstable, so the pottery was burned to the surface. On the other hand, the technique has improved and kilns have become more stable. From the point of view of those who wanted the old-fashioned retro tile, we noticed that the manufacturer's efforts were reversed." With this in mind, TILE made started by adjusting the amount of glaze by hand and daring to create the 'mura -tile' meaning tiles with uneven coloring instead of uniformity. TILE made is a brand that she joined the family business when she was 20 years old, and after a lot of experience, she launched while hitting a wall. In addition to my own experiences, my father's passion for manufacturing is the source of my current activities. Ms. Tamagawa said, "I feel the spirit of manufacturing engraved in my DNA every day while working. While destroying the situation where the tile industry is considered to be in decline by the public, we are pursuing activities that make people think that tiles are interesting. I also place importance on TILE made activities that involve people and bring out the "fun" in those people."

The tile-making process and its difficulties

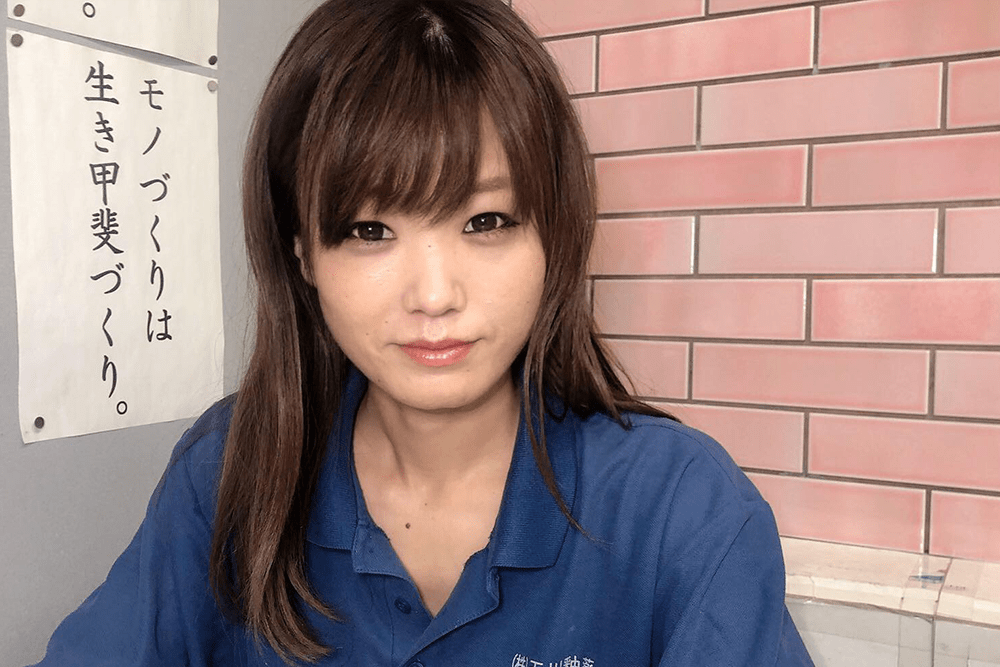

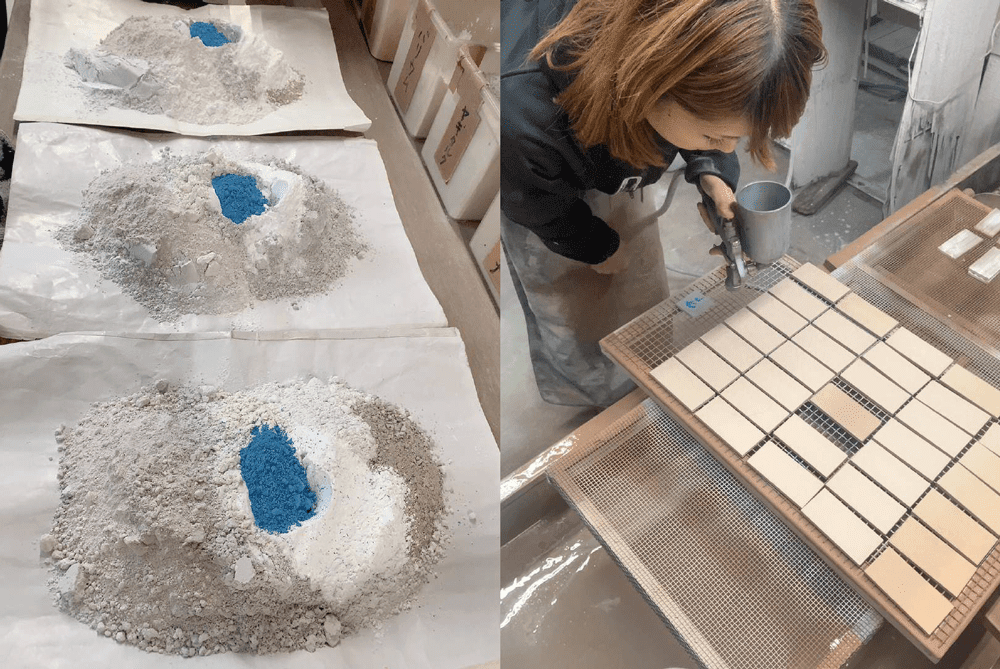

Following this, Hiroko Ido of Tamagawa Glaze inc., a sister of Ms. Tamagawa and a craftsperson of glaze, introduced the coloring technology and work process in the actual tile making.

When she creates a tile, she starts by looking at color samples with the customer to set the direction of the color and how it will be mixed. The coloring process involves lining up tiles, spraying them with glaze, and firing them. The finish of the baked tiles varies greatly depending on the mixing and amount of glaze. In addition, since the color only shows after the firing process, Ms. Ido shared that it is difficult to imagine the color of the finished product immediately after the glaze is sprayed.

In order to make one tile, more than 20 kinds of raw materials and pigments are blended together to give it color. When the balance is off even a little, the color doesn't come out as expected. In addition to the color pigments, adjusting the air pressure of the spray gun used can also change the tile surface, such as creating spots and indentations on the surface. The blending and spraying conditions are examined through daily experimentation to see whether the desired color and surface can be realized.

Creating something new with customers by exploring all the possibilities of tiles

"We want to take on the challenge of creating something new with traditional techniques,” said Ms. Tamagawa when summing up her presentation and speaking about her vision for TILE made activities.

TILE made has been challenging the development of various types of tiles, including tiles containing unevenness and cracks, tiles installed in photo spots, and tiles that use optical illusion to expand a space. The development of the blue mura-tile, which was meant to reproduce a photograph of the sky, was originally thought to be unsuccessful due to the spray being too soft and the color being too light from the perspective of conventional glaze technology. But the light color was praised by the customer as being "the color of the sky." "It is not up to the creator to decide whether something is a success or failure," Ms. Tamagawa said. "We are pursuing the full potential of new tiles, not with the feelings of the creator in mind but with those of the user."

Ms. Tamagawa described what she wants to realize with TILE made. " What I want to do with TILE made is not just to sell tiles, but to provide a view of world such as smiles and funny scenes for consumers through our tiles. I think the possibilities of tiles are endless, so I want to bring more of them out."

Then, at the end of the presentation, Ms. Tamagawa and Ms. Ido smiled and looked at each other, and on the screen there appeared a beautiful, red, shining lip-shaped tile. This event had prompted them to create original tiles inspired by Shiseido as a surprise for the participants. A rich red, which is said to be difficult to blend, was painted on the handmade, one-of-a-kind lip-shaped tiles, embodying the sheen of lipstick after it’s applied.

The online venue's chat box featured comments such as "How awesome!", "Cute!!" and "I definitely want one," and the presentation closed in an impressive way with the participants amazed at the planning and technological capabilities involved.

What are the commonalities between glazing and cosmetic technologies?

In the latter half of the event, a panel discussion was held by Ms. Tamagawa, Ms. Ido, Yusuke Nakano and Yukari Saito from the Shiseido Global Innovation Center, and Toyoda, a fibona member, as the host. Nakano is a researcher involved in R&D for lipstick, while Saito does R&D for liquid foundation.

When Saito asked, "With glazes, do the characteristics of the artisan sometimes get reflected in the product?" Ms. Ido immediately replied, "That's exactly the case, as the tile takes on the character of the artisan. Each artisan has their own unique characteristics, such as how to choose and blend glazes, and how to apply the glaze," she continued. “Also, the means taken to embody the customer’s order vary depending on the artisan. That's what’s interesting."

In the case of the development of cosmetics, Saito answered: "In the development of cosmetics, the individuality of the developer comes out in the product in the same way. For example, when developing products with a moisturizing effect, the individuality of the researcher will be reflected in the technologies and methods for selecting raw materials. The way of developing the feel and finish after application is precisely where the individuality of each researcher comes into play." The common approach between the two was to take an approach based on the individuality and ideas of engineers to realize consumer needs.

Subsequently, Nakano asked, "How do you measure ‘stability’ if you want to keep the tiles in a stable state"

Ms. Ido replied, "For example, when a tile is attached to an exterior wall of a condominium, they must be applied perfectly and neatly, with no unevenness in color. Since many tiles are used in some cases, standards of quality are set by figures measured by a color meter rather than by the human eye."

Nakano pointed out: "In the case of the lipsticks that I am in charge of, the coloring on the lips changes depending on the amount and depth of the pigments and the coloring of the customer's own skin and lips. Therefore, in contrast to Ms. Ido, evaluations (subjective evaluations based on the five senses) are emphasized, and values measured by equipment are used as a reference. This part is different from tile-making."

On the other hand, in response to the question of what is required of lipstick other than color, Nakano stated, "There are various factors such as shine vs. matte in terms of the finish, and other factors such as comfort vs. pearlescence." In response to this, Ms. Ido answered, "In glazes, in particular, the glossy finish is the most important factor for customers. On the other hand, the perception of the word "gloss" differs greatly from person to person, so it is important to accurately grasp that."

The difficulty of accurately grasping needs related to one’s sensibilities was the part that both glaze technology and cosmetic developers had a common awareness of.

The panelists were keen to talk together because glazes and cosmetics both involve techniques that handle the same 'colors'. Both types of developers have to realize the needs of customers by making full use of the technology, even though there are various uncertainties such as the condition of raw materials, and get closer to the goal while coordinating the image and perceptions of producers and users.

To realize consumer needs

Next, the moderator Toyoda asked the panelists, "What do you consider important to fulfill your consumers’ needs?" Ms. Tamagawa replied, "Orders from consumers can often be vague. What customers want to express is a certain worldview, so I try to listen carefully to what they want first. I try not to tell the craftsperson the wrong interpretation."

Next, Ms. Ido answered from the viewpoint of an engineer: "I think it is important to present things so that consumers can have a choice. I actually make several tiles that have different patterns to order, and communicate with consumers while showing them."

Saito responded to the same question as follows. "Our products are characterized by being used by an unspecified number of people that we are unable to meet. Some of our brands and products target the people who would want to use them the most, so we first try to get input from colleagues that fit our image of the target. Of course, my own sensibilities and experience are also important, but I try to get frank feedback from people who are close to the target."

Following that, Nakano answered, "We are aware of what we can do. For example, when a team of business planners propose a product, While thinking about what I would like to create if I was the proposer, we try to present several specific directions. We are predicting and developing future trends rather than this moment. From the consumer's point of view, We are working with passion while thinking about what the consumers want to achieve. "

The answers came from different perspectives, but all four mentioned a commitment to manufacturing done by trying to understand the customer's needs and realize them.

In the enthusiastic discussion by the panelists, various questions were asked by the audience, such as "Are you particular about materials from an ethical standpoint?" Dialogue continued in small group discussions among the participants.

The "beauty" and "craftmanship" that links different industries

At the end of the meeting, a session was held in which each participant wrote their impressions on the sheet used in the ice breaker. One participant commented, "I was very impressed with the story of creating a worldview as well as a product." It was evident that various discoveries were made by the participants.

Ms. Tamagawa shared her impressions of the two-hour event.

"I found it interesting to be able to discuss totally different things, i.e. tiles and cosmetics, under the concept of beauty. I was able to learn different meanings of our activities from different perspective, which gave us a lot of confidence. In the glaze industry, there is absolutely a distance between the technicians and the customers who ultimately use the products, and there are times when I lose sight of what we’re making products for. Through discussions with people who are making the same kinds of products today, I felt once again that I wanted to work closely with customers and pursue the creation of truly good products."

Finally, the closing message was shared. "From the perspective of cosmetics development, there were many commonalities and discoveries, such as the fact that the personalities of craftsmen and developers appear in manufacturing, and the fact that they can be translated while showing physical things and making them available for common interpretation and utilization in manufacturing." Yuko Nakanishi, the leader of fibona, said, " Ms. Tamagawa's actions not only come up with new ideas, but also involve many people to carry them out, making them happy as well. I learned a lot from the perspective of promoting manufacturing and the ability to execute new things."

Even after many years of research, glaze technology and cosmetic technology are still profound technologies. In the future, engineers will continue to pursue their technologies in depth. On the other hand, customer needs are expanding and continuing to diversify. In this age of rapid change, this event was filled with a lot of insights about how customers should be the starting point in manufacturing products.

Yukie TAMAGAWA Yukie Tamagawa joined Tamagawa Glaze, Inc. in 2003 while continuing to work around the world and conduct volunteer activities to pick up trash, etc., in order to build personal connections and spread knowledge. In 2011, she moved to Tokyo, where she founded Protb LLC after training in a number of companies as a project manager. In 2017, she launched TILE made, a brand of custom-made tiles that leverages glazing techniques. Since then, the company has been working to revitalize the family business and local industry based in Mizunami City. (Protob LCC. https://www.protob.com/ , TILE made https://TILEmade.jp/ , Tamagawa Glaze inc. http://tamagaway.jp/ )

Project

Cultivation

Activity